To assess workplace hygiene and the level of exposure workers face, it’s essential to understand the meaning of permissible exposure limits as defined by Mexican authorities: VLE, VLE-CT, VLE-P, and VLE-PPT. In the United States, well-established organizations like NIOSH, ACGIH, and OSHA also set these exposure standards—known as TLV, TLV-STEL, PEL, and TLV-TWA—and these terms are commonly used throughout industry. For this reason, it’s important to understand how these U.S. standards correspond to the Mexican regulations:

Permissible Exposure Limit (VLE or TLV): This is the reference concentration for a chemical contaminant in workplace air, which can be averaged over time, measured over a short-term period, or noted as a peak value. It’s expressed in milligrams per cubic meter (mg/m³) or fibers per cubic centimeter (f/cm³) under actual sampling conditions, and in parts per million (ppm) under standard temperature and pressure (STP).

Short-Term Exposure Limit (VLE-CT or TLV-STEL): This is the maximum concentration of a chemical contaminant to which workers can be exposed continuously for up to 15 minutes, with at least one hour between exposures and no more than four such periods in an eight-hour shift. Importantly, this limit cannot exceed the time-weighted average exposure limit (VLE-PPT or TLV-TWA).

Ceiling Limit (VLE-P or PEL): This is the concentration of a chemical contaminant that should never be exceeded at any time during the workday.

Time-Weighted Average Limit (VLE-PPT or TLV-TWA): This is the average maximum concentration of a chemical contaminant to which most workers can be exposed over an eight-hour day and a 40-hour workweek without adverse health effects.

In the U.S., different institutions set these standards for specific applications: NIOSH (National Institute for Occupational Safety and Health), ACGIH (American Conference of Governmental Industrial Hygienists), and OSHA (Occupational Safety and Health Administration), with OSHA being the regulatory authority whose limits are legally enforceable. In the table below, you’ll find an example comparing permissible exposure limits from various organizations. Some terms—such as REL (Recommended Exposure Level), Ceiling Limit, and IDLH (Immediately Dangerous to Life or Health)—are not included in Mexico’s NOM-010 standard.

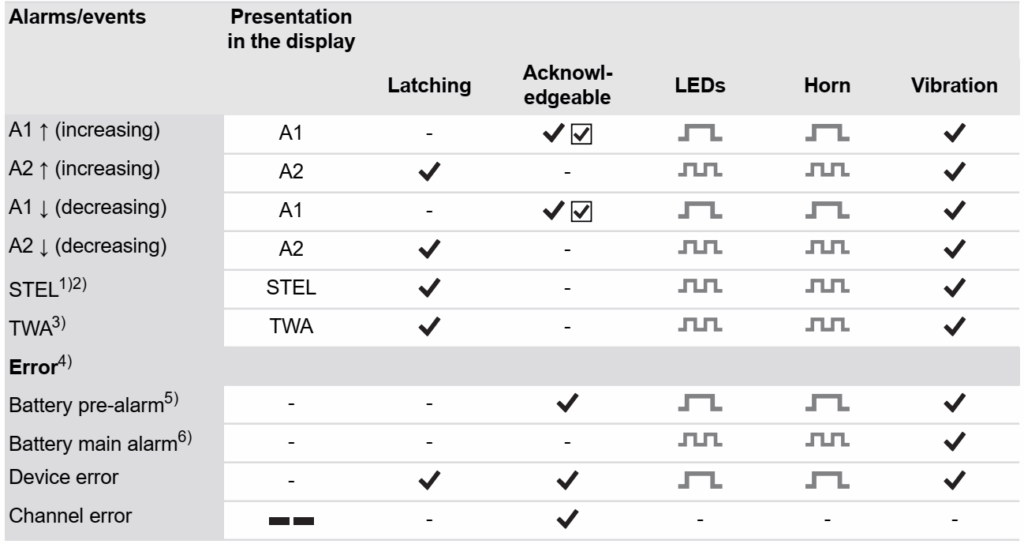

So, how do you know if a worker is in a harmful or dangerous environment? That’s where portable gas detectors come in. These mobile devices continuously monitor air quality, and some models—like Draeger’s X-am series—feature integrated data loggers, event recording, and visual/audible alarms that alert users when exposure limits are reached. They also record events and data for later download and analysis on a computer. The graphic below illustrates how these exposure levels are communicated to users.

Finally, NOM-010 Table I.1 lists the most common industrial substances in Mexico along with their permissible exposure limits for an 8-hour shift (VLE-PPT) and for 15-minute periods (VLE-CT). If you need assistance selecting the right gas detector for your application—or require support with maintenance and calibration—please don’t hesitate to contact us. We’re here to help you choose the right equipment and keep it operating safely and effectively.